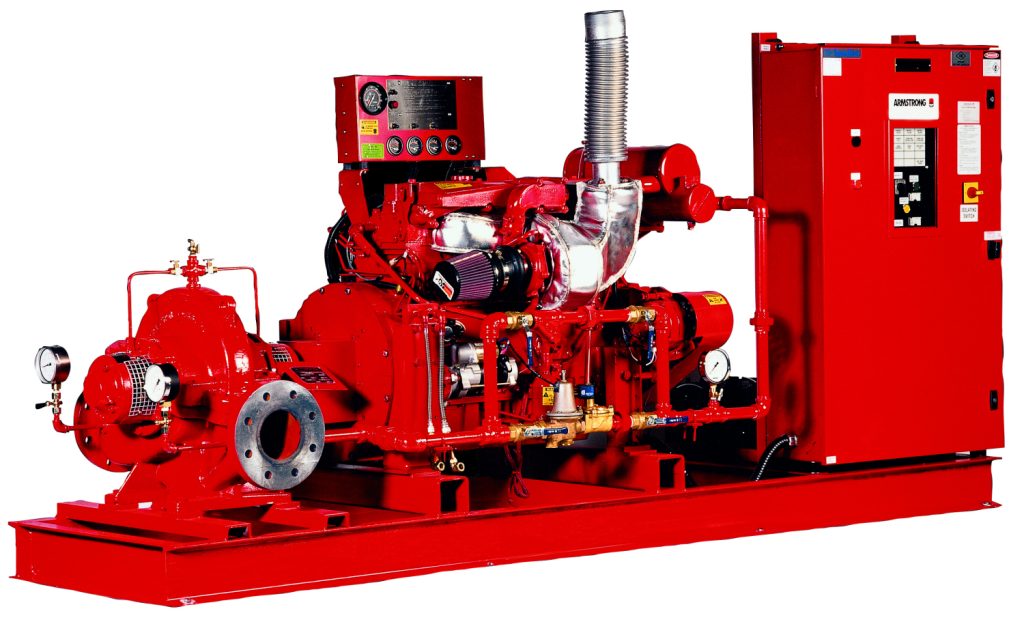

Fire pumps sit, usually silent and nondescript, in the basements and bottom stories of high-rise buildings. But in the event of a fire, they send water at high pressure to sprinklers throughout a structure. Fire pump power requirements put a lot of demands on the electrical system. It’s important to understand their operating principles, types and driver options and how they’re sized to meet NFPA standards. Split Case Pumps A split case pump is a popular choice for transferring water in firefighting applications. These pumps are commonly used to supply water to fire hydrants or to operate fire sprinkler systems. They are also often used to move wastewater in industrial applications. The split case design allows for easier maintenance and repair, and they are often cheaper than long-stroke or vertical centrifugal pumps. This type of centrifugal pump has an impeller that is located between two bearings. It is a versatile and durable fire pump, but it can be limited in how much pressure it can handle. This is because the impeller is not supported by a casing as it is with other types of fire pumps. Typically, split case pumps can handle up to 175 psi, and they are well-suited for use in many different applications. They can move a wide range of fluids, including corrosive liquids like acids and solvents. In addition, the split case pump is less likely to develop leaks compared to other pump types. The swivel on the top of the split case pump is the most common type of connection that is used to attach it to the hose. This connection is typically 2.5″ NH aka NST, but it is important to check with your local fire department to make sure that this is the correct thread size for your application. This type of fire pump can be installed on a pedestal or in-ground installation, and it can also be mounted in a fire truck or water tower. This design is ideal for locations where space is limited. Because these fire pumps have a smaller footprint than frame-mounted models, they are easy to fit into tight spaces. They also have a higher efficiency than other types of fire pumps. Additionally, split case pumps are easier to maintain than other types of fire pumps because the rotor is easily accessible without disturbing the casing or motor components. The horizontal split case fire pump is designed to have a double suction design that promotes optimal efficiency and minimizes axial thrust. This allows the fire pump to deliver large water flows with a low horsepower, which reduces energy costs. Additionally, the double suction design helps to prevent water turbulence from damaging the pump and reducing its lifespan. These fire pumps are commonly used in commercial, residential, and industrial high-rise buildings, power plants, airports, and other large facilities. They can also be found in cooling towers, irrigation, and district heating systems. Split case pumps are known for their durability and reliability, making them the industry workhorses. However, they are not without their limitations. They are sensitive to the presence of horizontal elbows (or other piping constrictions) on the suction side, which can induce asymmetrical pressure and lead to bearing and seal failures. They are also susceptible to vibration, which can damage the impeller shaft and cause premature wear. As such, it is important to ensure that these pumps are not exposed to any environmental conditions that could damage their components. fire pumps for sale