Ppr pipe fittings are vital components in plumbing and fluid transportation systems. They are used in a wide variety of residential, commercial, industrial, and agricultural projects and offer numerous advantages such as high temperature and chemical resistance and ease of installation. Moreover, they are unaffected by corrosion and have the ability to withstand various environmental conditions.

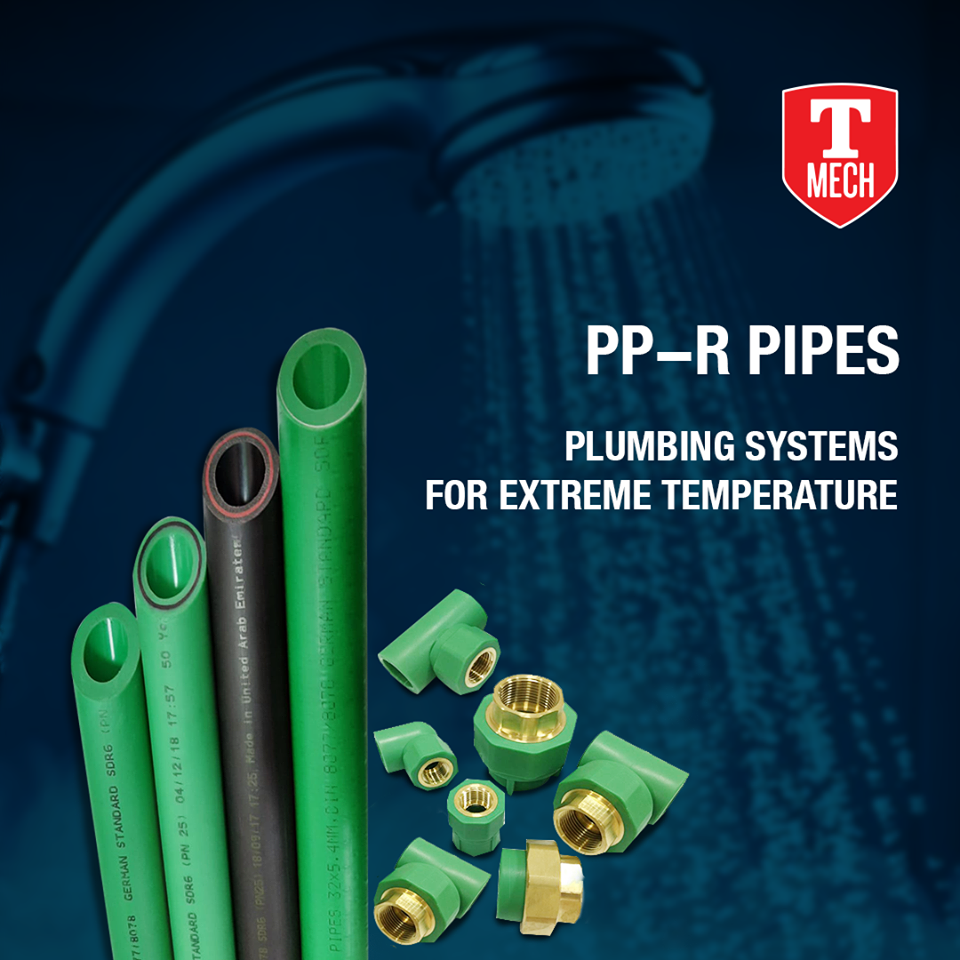

PPR stands for polypropylene random copolymer, and is a type of plastic pipe used in water supply and drainage systems. It is a highly durable pipe, and can withstand both hot and cold water pressures. It is also resistant to chemicals and is able to withstand UV light, making it an excellent choice for use in industrial applications. In addition, ppr pipes are extremely easy to install and require no special tools or materials.

The manufacturing process begins with high-quality PP granules, which are then melted and extruded into pipes or injection molded into fittings. These fittings are then socketed or welded together with the pipes to create a complete system. This method of connection is known as fusion welding, and it produces a strong and durable system that will last for many years.

When it comes to installing a PPR pipe system, the first step is to prepare the work area. This should include clearing the area and removing any debris or other obstructions from the site. Next, mark the lines where you want the pipe to be installed. Make sure that the markings are clearly visible, and that they line up with the joints. Once you have marked the lines, you can begin installing the pipe and fittings.

In order to ensure the quality of pppr pipe fittings, you should always look for a manufacturer that has stringent quality control measures in place. The manufacturer should also have a certification from the national standardization commission. In addition, the manufacturer should have a sanitary performance inspection report from the health inspection department.

The hygienic properties of pppr pipe fittings make them an ideal choice for plumbing systems in hospitals and hotels. They are odorless, tasteless, and colorless, and do not change the appearance or flavor of water. They are also resistant to rust and other environmental factors, which means that they can be safely used in food processing plants.

PPR pipe fittings have a low thermal conductivity, which helps to save energy by minimizing heat loss. In addition, they have a smooth inner surface that reduces friction and allows for a higher flow rate. They are also easy to clean and maintain, and can withstand a wide range of temperatures.

Compared to traditional metal pipe systems, PPR pipe fittings are much easier and safer to install. This is because they do not contain lead or other toxic chemicals and have a lower risk of corrosion. In addition, they are lighter than other metal pipe types, which makes them less expensive to transport and install. PPR pipe fittings can be used in residential and commercial plumbing projects, and are an excellent alternative to copper and galvanized steel pipe.