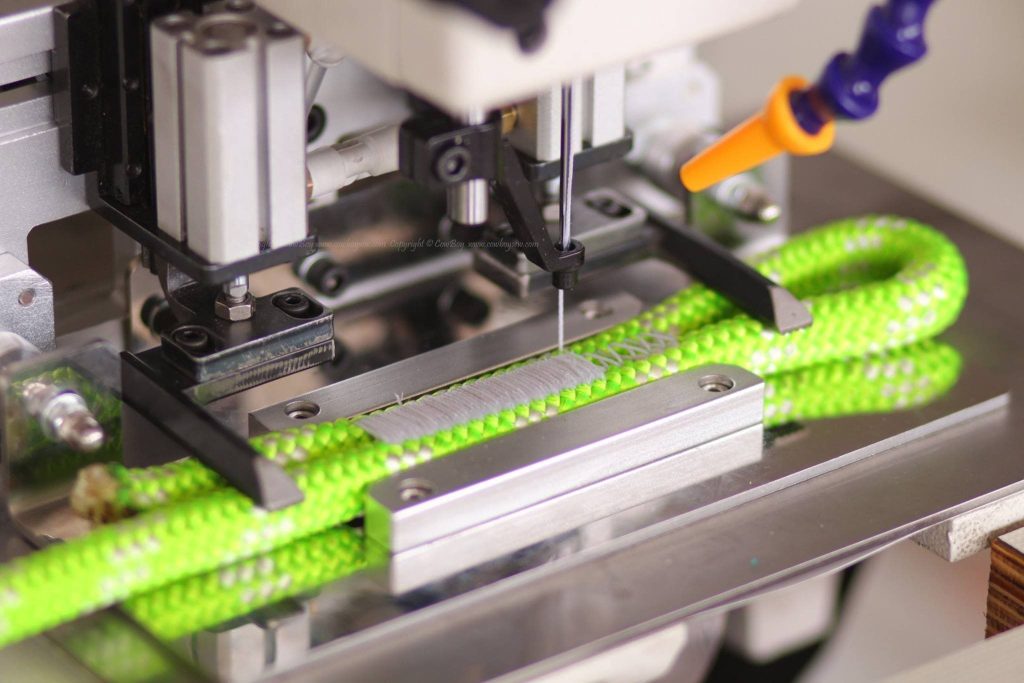

Eyeleting machine is a necessary tool used in the high-quality marketing and production industry. It combines punching and eyelet insertion in one machine.

The process of inserting eyelets by hand can be laborious and inefficient. It can also create inconsistent results due to natural variance in crafter technique. This machine does all the work in a single operation, eliminating these problems.SizesThe eyeleting machine comes in a variety of sizes. The size is determined by the diameter of the eyelet and the flange thickness. It can be manually operated or powered by an electric motor. It can also be equipped with a pre-punching device to help reduce time and labor.A manual eyeleting machine is used for applications that require multiple eyelets. It punches and sets the eyelets at the same time. The machine is suitable for a range of eyelet sizes and shapes, including brass, stainless steel, and plastic. It is a great choice for applications that use a lot of eyelets in PVC tarpaulins, shoes, textiles toys manufacturers etc.The PM-1 pneumatic eyelet machine can save a lot of labor and is more efficient than a manual eyeleting machine. It works only need one single eyelet, no need washer, and can go through mainly PVC flex banners. The machine is also easy to move around, making it ideal for mobile applications.MaterialsEyelet machines use a variety of materials to create the eyelets that are used on various types of fabrics. Brass, aluminum, and steel are the most common materials. These metals are strong, durable, and can be made into different shapes to accommodate a variety of applications.These machines are usually equipped with a pair of eyelet dies, and they can be adjusted to change the size of the holes in the fabric. The machine can also be set to automatically bind and punch eyelets in one pass. This makes the process faster and more efficient.This type of eyeleting machine can be used to attach eyelets and grommets to any type of fabric or material. It can also be used to seal bags and cardboard boxes. The machine is easy to use and is highly reliable. It is designed to be safe and effective, and it can be used by workers of any skill level.ApplicationsWhether it’s for reinforcing banner materials or fastening tarpaulin, an eyeleting machine can be used in a wide variety of applications. These machines punch holes and attach eyelets in fabric, making them a necessary tool for any marketing or production business.Unlike hand presses, eyeleting machines are designed for large production cycles. They can handle a higher volume of projects in a shorter period of time, saving businesses money on labor costs and increasing their efficiency.Choosing the right eyelet machine is critical for ensuring the best results. Look for one that works with a range of materials and sizes, so you can use it in various applications without having to swap machines. For example, the Eurotech 333PC has adjustable settings that can work with all sizes of eyelets, as well as flute sheets and banner materials. It also features a double head and automatic feeding to boost productivity. Its precise thickness adjustment allows for a consistent eyelet application and reduces the risk of damage to sensitive fabrics.SafetyWith the advent of technology, modern eyeleting machines offer a wide range of safety measures. The machines have pressure adjustment systems, the ability to replace ferrule tips, and photocells that prevent the machine from operating when an unknown object is detected. These safety features help reduce injuries and increase efficiency.An eyelet machine punches holes and sets eyelets or grommets with washers in one operation, making it an ideal choice for a variety of applications. It is easy to operate and is suitable for a variety of materials, including fabric.When using an eyelet machine, it is important to follow the instructions carefully. It is also important to use a quality set of eyelets and grommets. An eyelet machine can save time and money for businesses by reducing production times. In addition, it can improve the appearance of fabric items and make them more attractive. A quality eyelet machine is an excellent investment for any business.