Cold drawing is a process that increases the strength and reduces the brittleness of steel. It is a cold deformation process that uses monolithic dies. The energy-power parameters of the drawing process are influenced by various technological factors such as the drawing speed, route and die angle.

Carotron provides Elite Pro Digital DC Drives to control a variety of wire drawing capacities, ferrous and non-ferrous. They are also used to retrofit older drawing machines whose AC drives cannot be replaced.

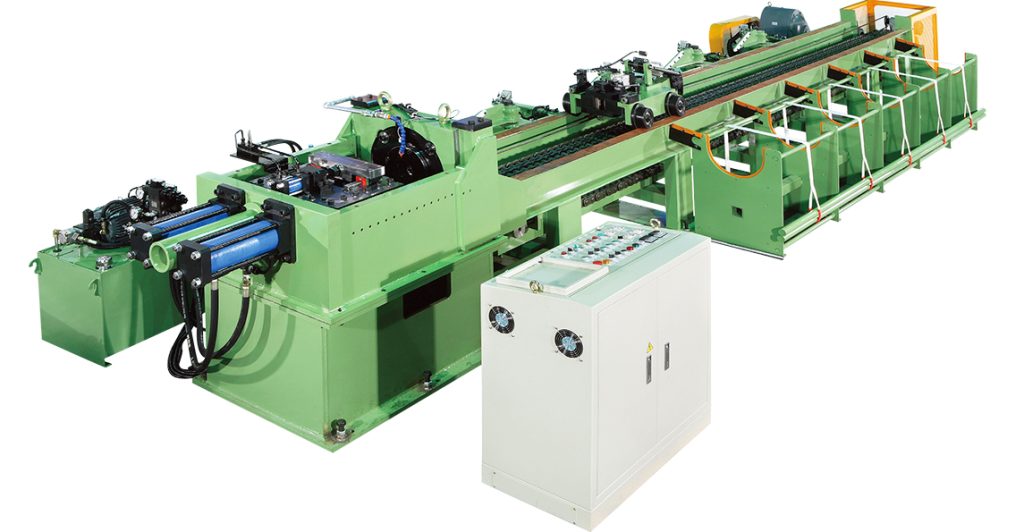

HS Model

The HS model Cold drawing machine is designed for industrial applications that require a high degree of re-sizing, with consideration in precision and mechanical properties. It is a chain-type machine that can be used to draw metallic tubes and bars with a wide variety of shapes and dimensions. The system has a hydraulic push pointer to press the material into the cold drawing dies. It is also equipped with a mechanical pointing machine to narrow the tip of the raw wire before drawing.

The new computer simulation, using a one-dimensional explicit finite difference method and a redundant work formulation, accurately predicted the performance of the multipass drawing process. The simulation also indicated optimum semi-die angles away from the traditional eight degrees, a change that significantly reduced the stress ratio and drawing force.

Distributor of new & used machines, tools, equipment & parts for metal fabrication & welding. Capabilities include CNC machining, lathe cutting up to 500 mm dia., milling up to 4 m long between centers, surface, cylindrical & jig grinding for a range of sizes & materials, wire EDM, band & circular sawing & inspection. HS is also a custom manufacturer of dies for a broad range of industrial products including wire, cable, hose & tube.

SS Model

Cold drawing is a process that reduces the cross section of a rod or coil, shapes it and increases its length. It requires a high level of mechanization and automation to achieve the desired product. Moreover, it generates considerable heat and produces large amounts of scrap metal. The main advantage of this type of drawing is the ability to produce a bright, polished and/or polished finish, increased mechanical properties, improved machining characteristics and superior dimensional tolerances.

A water-cooled block improves drafting speed by 45%. This is an important advancement for heavy machines used to draw abrasive copper, pre-stressed concrete and other high carbon wire products. Its design eliminates the use of multiple sheaves and recirculation of wire which reduces heating, friction and scratching. This type of block is also able to provide a small amount of accumulation, which helps control speed.

The motors that power the capstans on a drawing machine require special construction to withstand the harsh physical and electrical environment in which they operate. For example, they must be designed to handle the large voltage spikes that occur in the AC drive and must have a sufficient cooling fan to prevent overheating. A nonventilated motor may be used for lower-power systems, but this is not a good option for larger systems.

A state-space model consists of input, output, and state variables related by first-order differential equations. You can use ss to create real-valued or complex-valued state-space models, and to convert dynamic system models to state-space model form. ss can also be used to create generalized (genss) or uncertain (uss) state-space models.

The SS, which included police forces and special military units, was an independent group responsible directly to Hitler. Its head, Heinrich Himmler, was a racist fanatic who screened applicants for physical perfection and racial purity. In 1934, he created the Allgemeine SS and the Waffen-SS and expanded their responsibilities and activities. With its sleek black uniforms and special insignia (lightning-like runic S’s, death’s head badges, silver daggers), the SS was seen as physically and morally superior to the brawling brown-shirted storm troopers of the SA, to which it initially was nominally subordinate.

Create a second state-space model, sys2, with the time unit and input unit properties inherited from sys1. Name the output variable Force, and set its value to 1. Create a step response plot for sys2 versus time, and verify that the values of the state variables are consistent with the input variable dimensions. Repeat the process to create a step response plot for sys2 against time for the static gain MIMO state-space model.